Printed Circuit Boards, or PCBs, have been influencing our lives since 1950 in ways that we take for granted. From the ordinary desktop computers to complex medical devices and automotives, PCBs are literally everywhere. There are countless resources that are used to manufacture PCBs and the hard work and effort it entails is normally ignored by the consumers of electronic products. Even if you have a vague idea of the designing and manufacturing process of PCBs, you would easily find out how useful yet complex this technology is.

Printed Circuit Boards, or PCBs, have been influencing our lives since 1950 in ways that we take for granted. From the ordinary desktop computers to complex medical devices and automotives, PCBs are literally everywhere. There are countless resources that are used to manufacture PCBs and the hard work and effort it entails is normally ignored by the consumers of electronic products. Even if you have a vague idea of the designing and manufacturing process of PCBs, you would easily find out how useful yet complex this technology is.

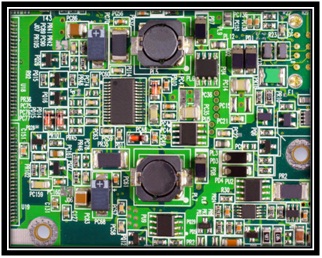

To begin with, a printed circuit board consists of a copper printed pattern over a glass or a plastic board (substrate). The pattern of the electrical components over it are organized in such a way that electricity flows to the required parts of the board. It is the electrical components that control the behavior of the electric current across resistors, transistors and amplifiers.

The Industries

PCBs are used in a large number of industries. One of the most common uses of PCBs is in the sensors and semiconductors of airplanes, missile wing sensors, and other aerospace engineering devices. PCBs are also used in the Defense and Military industry and integrated into missiles and rockets. The fact is that almost all the latest electronic gadgets that we know today have PCBs incorporated. It wouldn’t be wrong to say that printed circuit boards are more like a solid avenue in the industry’s trail of the smallest possible circuit device. One of the most amazing uses of PCBs is the microchip dog implants designed specifically for dogs.

PCBs are used in a large number of industries. One of the most common uses of PCBs is in the sensors and semiconductors of airplanes, missile wing sensors, and other aerospace engineering devices. PCBs are also used in the Defense and Military industry and integrated into missiles and rockets. The fact is that almost all the latest electronic gadgets that we know today have PCBs incorporated. It wouldn’t be wrong to say that printed circuit boards are more like a solid avenue in the industry’s trail of the smallest possible circuit device. One of the most amazing uses of PCBs is the microchip dog implants designed specifically for dogs.

Engraving

On a very basic level, a PCB is a substrate with a printed pattern. This pattern indicates the direction and flow of electrons on the PCB’s surface. In order to permit these electrons to move freely, this pattern is engraved on the substrate with the use of copper. For etching purposes, a sheet of copper is cut according to the size of the substrate. Then, a resin material such as Epoxy is applied over the surface of the substrate and the copper sheet is laid over it and pressed down. The engraving machine cuts out additional copper and forms a circuit pattern.

Silk-Screen Printing

This is a different method used for printing PCBs. It requires printing of the circuit board pattern over a substrate using a silkscreen printer. The ink that’s used in the process is basically an electricity-conductive ink such as India ink; therefore, when applied on a printed pattern, it permits the electrons to pass through and travel along freely.

This is a different method used for printing PCBs. It requires printing of the circuit board pattern over a substrate using a silkscreen printer. The ink that’s used in the process is basically an electricity-conductive ink such as India ink; therefore, when applied on a printed pattern, it permits the electrons to pass through and travel along freely.

Knowing that not all PCB manufacturers adhere to their claimed standards of quality, Super PCB is recognized as the ultimate reservoir of high-quality PCBs. We provide Rigid and Flex PCB to meet the expectations and needs of businesses across diverse industries. Serving the market since 2003, we have established a rock-solid reputation of providing first-class prototype printed circuit boards. Find more about our printed circuit board production facilities or have a look at our PCB process in a glance.